QUAD SEAL

The purpose of this document is to give guidance to approved contractors and suppliers who are engaged in the fire stopping of fire rated structures using Quad Seal. All Timber fire door assemblies must be fire stopped to prevent the passage of fire, smoke and hot gases. The key points for passive fire protection products are :-

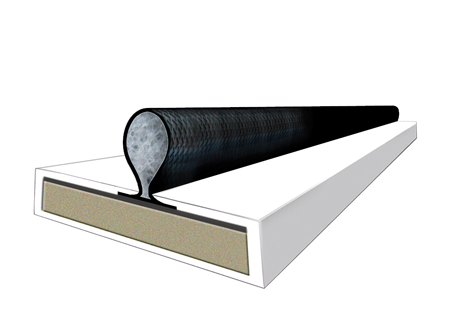

If your fire door or frame is not pre-grooved check the door manufacturers data and test sheets to establish the size and quantity of intumescent seals required. You should also note the tested position of the seals and whether any additional protection is required around the particularly vulnerable areas of the lock and hinges' Rebate the door or door frame to accommodate the chosen seal which should be fitted so that the PVC sleeve finishes flush with the face of the timber. An allowance in the rebate width may be necessary to allow for timber shrinkage or for paint/stains, so we recommended grooving 3% greater than the chosen seal size. We recommend that the gap between door and frame should be no greater that 4mm. To fix remove the release paper from the self-adhesive backing tape and push the seal firmly into the rebate along its full length. Periodically check seal to confirm the integrity.

Composition: Density: 1025 Kg/m3

Certifire approval CF 276

|